The automation of Arania’s Smart Factory: a success story at BeDigital3

As our regular readers already know, the implementation of a state-of-the-art automated warehouse in the heart of the production site has been one of the most important milestones in Arania’s automation programme. This project is acting as an innovative booster for the company’s transformation towards the future Smart Factory, establishing an excellent model that can be replicated in other areas of the factory.

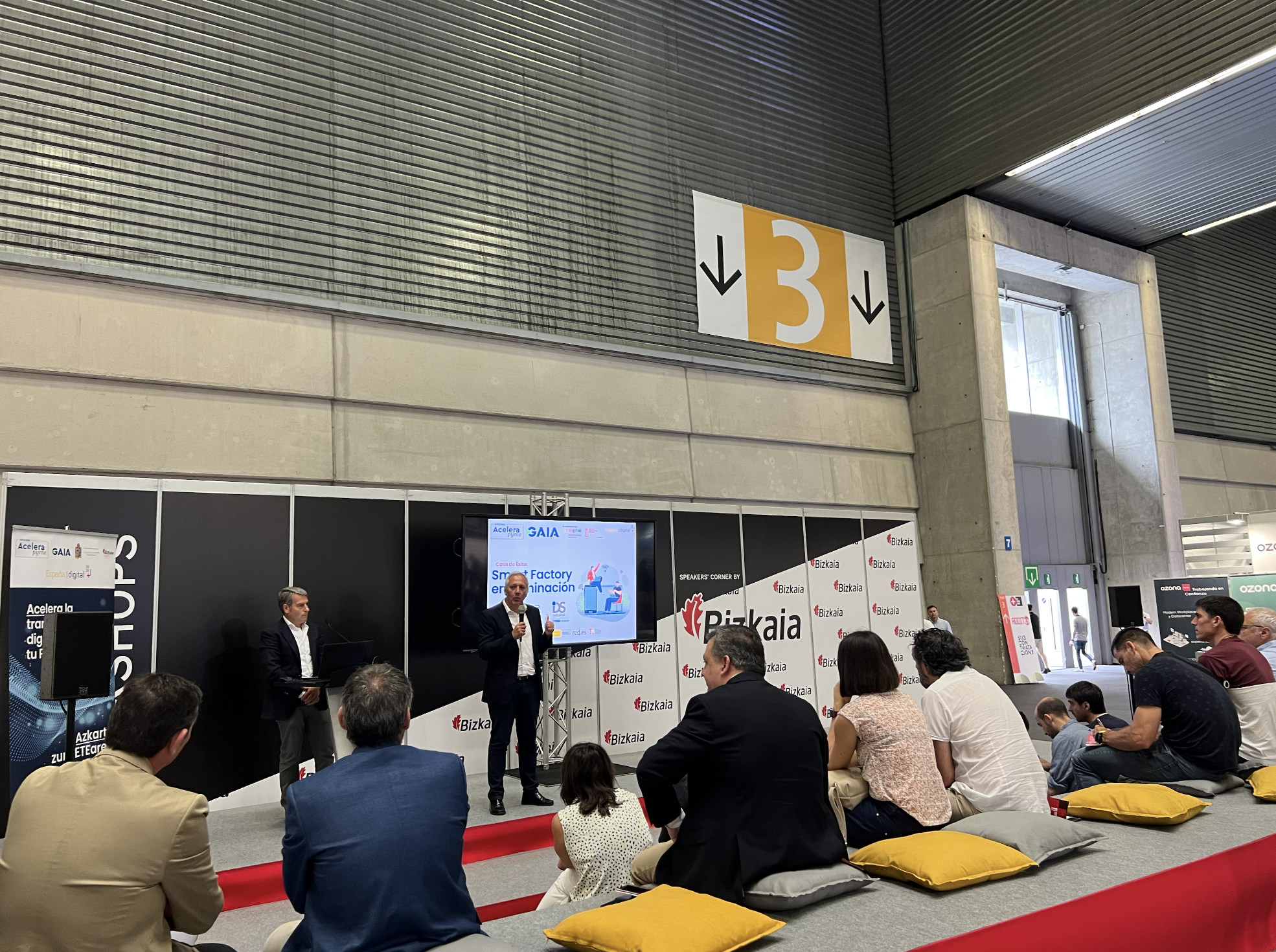

This is how the innovative automated warehouse developed by Arania has been selected as an outstanding and successful example of success in the industrial automation of rolled steel, chosen to be presented at the conferences organised as part of BeDigital . This major industrial technology exhibition, held at the Bilbao Exhibition Centre (Basque Country, Spain) as part of the major industrial trade fair +Industry attracted leaders and experts from all over the world to share knowledge, expertise and achievements regarding the digital transformation of factories.

Arania’s presentation at BeDigital recognises the company’s achievements in its transformation process towards the Smart Factory. On this occasion, Arania was selected to showcase its processes and highlight the benefits resulting from the automation of its rolled steel plant. Iñaki Lopategi, Head of Investment Projects and Manufacturing Technologies at Arania, was in charge of sharing his experience. An enthusiastic audience received detailed information explaining the actions carried out, the results obtained and the challenges faced on the long road leading to the factory of the future.

The setup of automation processes and new machines in key areas such as the external automated coil storage, automated intralogistics trolleys, the automated intermediate warehouse and automated product packaging are among the ‘visible’ examples of the actions taken to boost efficiency and productivity in the factory.

At the same time, Arania has reengineered certain stages of the production process, including the installation of a Manufacturing Execution System (MES) enntte®, allowing for complete control over resources, materials and all stages of the rolled steel manufacturing process, from the reception of raw materials to the dispatch of the finished product. All in all, it provides complete supervision of an entire industrial plant.

These projects, where automation leads the way, have resulted in a number of significant benefits for Arania and its rolled steel plant, and ultimately this is the key points that deserve to be highlighted when presenting a success story at a renowned industrial conference such as BeDigital. One of the most outstanding results, as Iñaki Lopategi recalled, has been the increase in productivity, enabling the company to achieve higher levels of efficiency throughout its operations.

The ability to react to unforeseen events has been significantly improved: the automation of processes and the real-time monitoring of processes involving the entire plant have been optimised, with better use of time at all stages of production.

The traceability of products has also been improved, reinforcing the strong commitment of Arania to guarantee the quality of its products and offering a higher level of confidence to its clients, even in times of market turmoil. Self-management of operations has been simplified and optimised, culminating in improved management of rejects. In addition, the manufacturing line experienced a remarkable optimisation thanks to the automation of key processes, acting as a catalyst for greater efficiency in the rolled steel production process.

The successful implementation of automation throughout its rolled steel plant has established Arania as a reference in the steel sector, leading the way towards the factory of the future in Southern Europe’s rolled steel industry, demonstrating its ability to adapt to technological advances and constantly upgrading its operations. Arania’s forward-looking approach, together with its commitment to innovation, has provided flexibility to meet the changing demands of the market, and has also enabled to keep growing in terms of quality and customer satisfaction at the same time.

Tamara Yagüe, president of the Federation of Metal Companies of Bizkaia (FVEM), inaugurated the great event + Industry, where Be Digital is included, together with the participation of GAIA “This is a not to be missed event for all the companies in our sector, as well as for the industry as a whole”.

Arania was a leading player at this year’s BeDigital, an event at the forefront of the industrial sector, offering a unique platform to discuss the latest technological advances and success stories in the field of digitisation of production. Focused on new technologies and the industrial processes for the future, this congress brings together professionals, researchers and representatives from cutting-edge companies, offering an ideal environment for the exchange of ideas and new opportunities for collaborative projects.